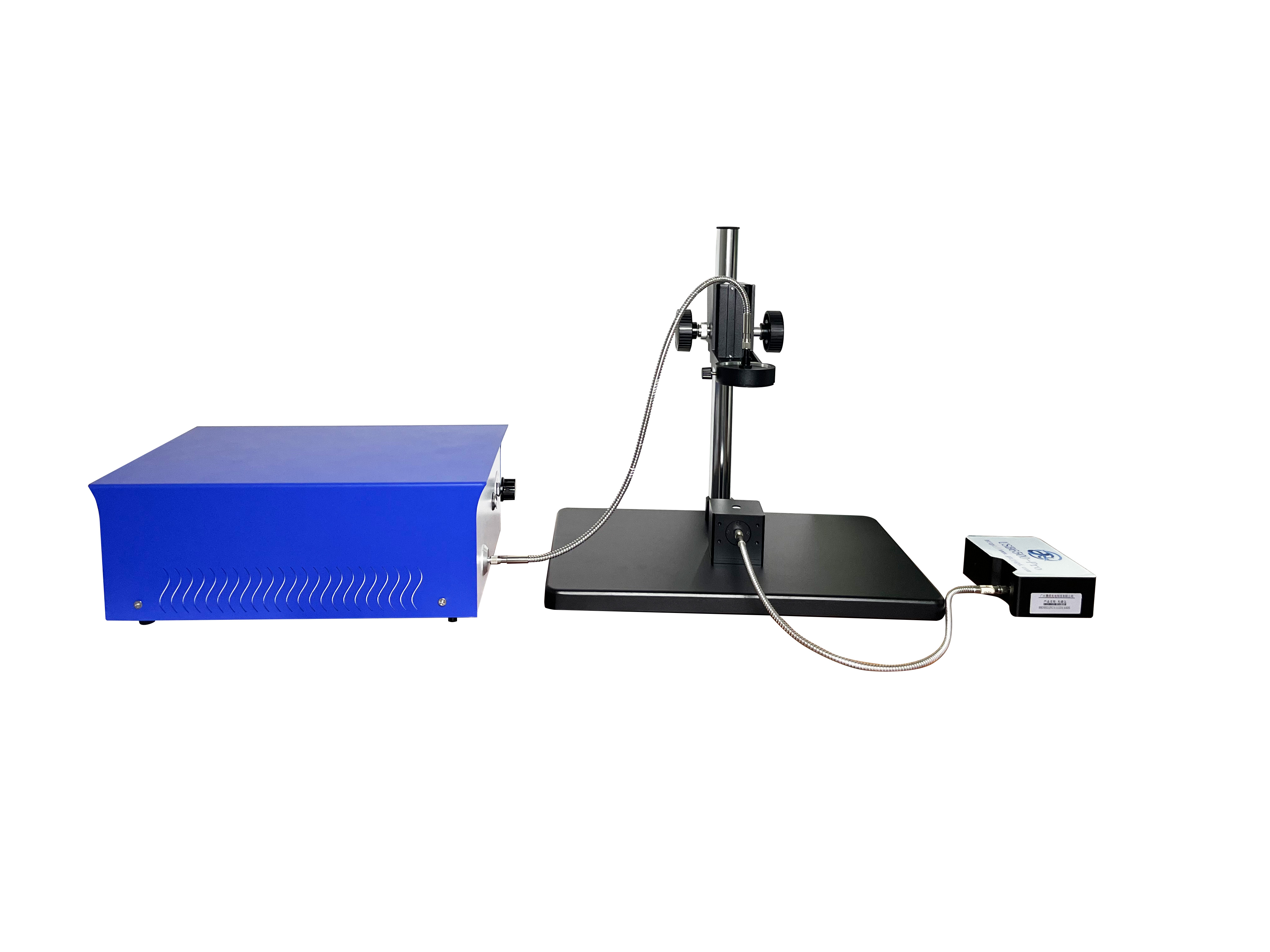

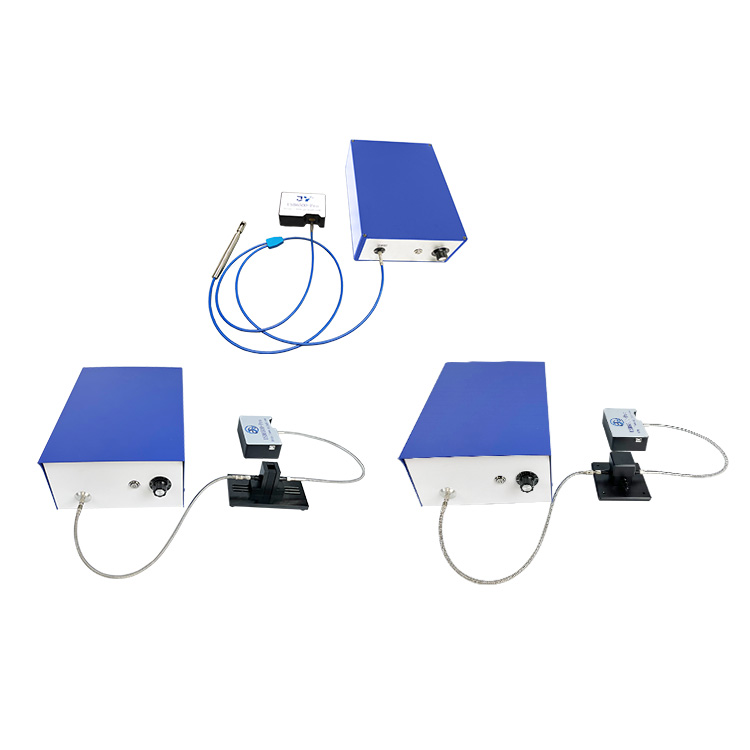

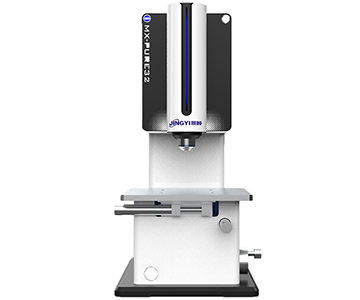

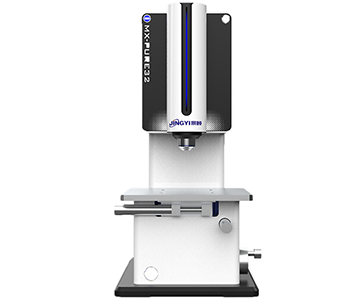

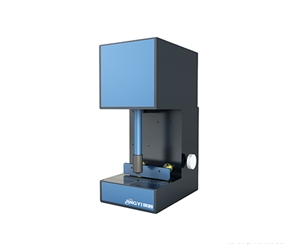

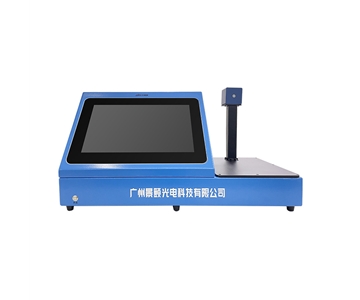

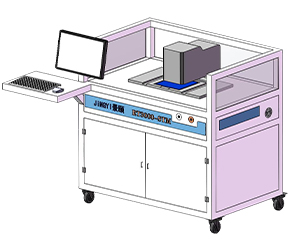

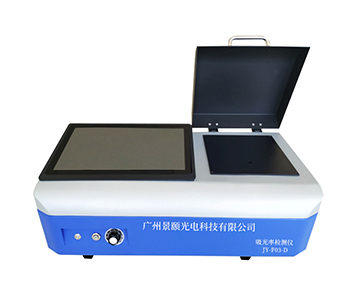

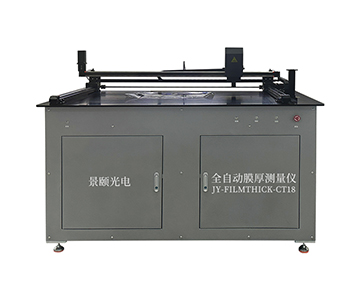

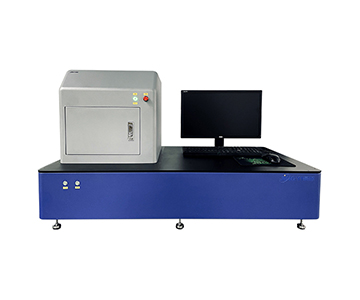

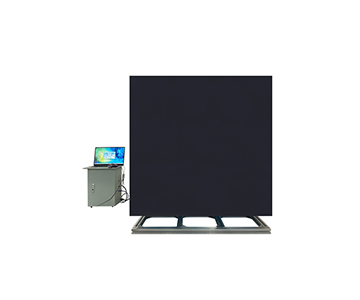

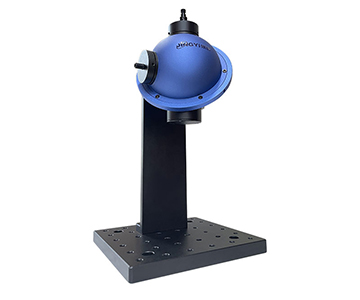

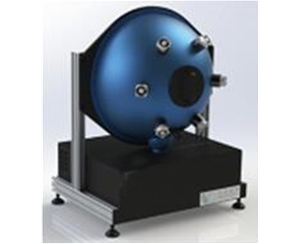

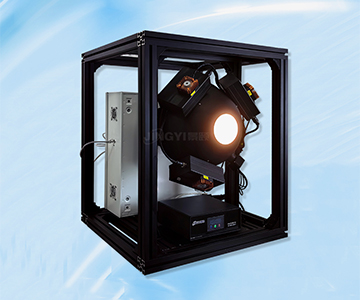

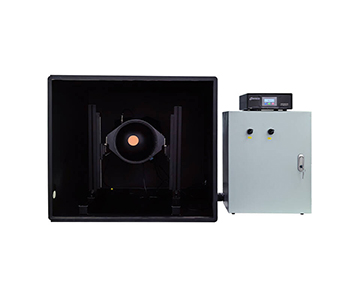

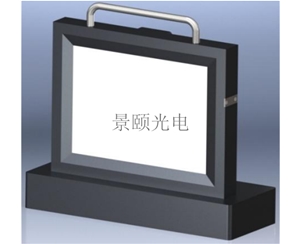

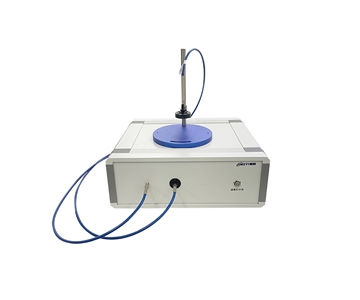

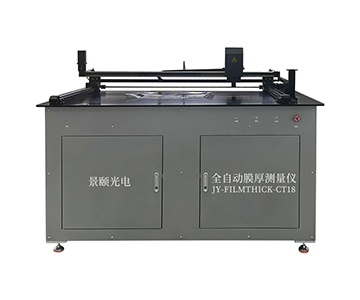

In today's era of rapid technological advancement, thin film technology is widely used across numerous fields such as electronics, optics, coatings, and biomedicine. The film thickness detector, as a core instrument for precisely measuring film thickness, is of paramount importance. Taking the Jingyi Optoelectronics Film Thickness Detector FILMTHICK-C10 as an example, it provides film thickness measurement solutions for various industries, leveraging its technological principles and performance.

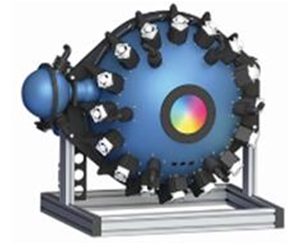

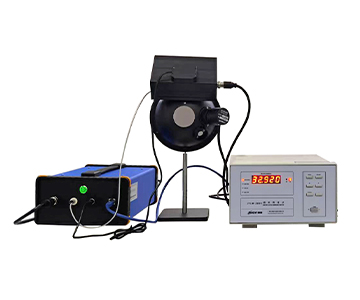

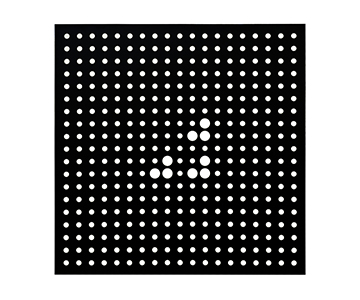

The Jingyi Optoelectronics Film Thickness Detector FILMTHICK-C10 utilizes the principle of optical interference to measure film thickness. When light irradiates the film surface, reflection occurs at the upper and lower surfaces. These two reflected beams interfere with each other, forming interference fringes. Through detailed analysis of these interference fringes, combined with optical principles and mathematical algorithms, the film thickness can be calculated. This non-contact, non-destructive measurement method not only avoids damage to samples but also ensures the accuracy and reliability of the measurement results.

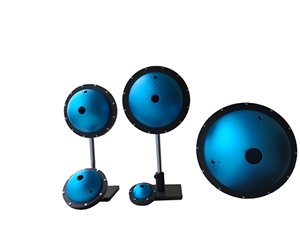

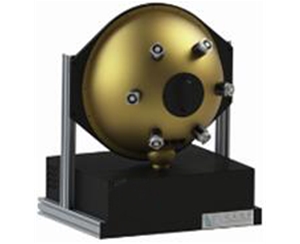

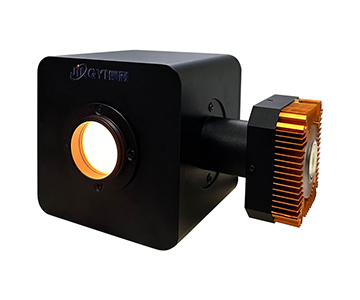

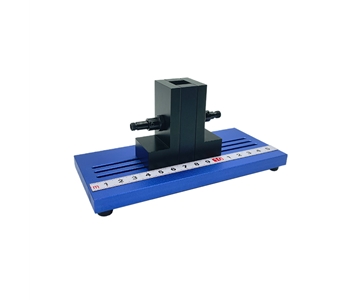

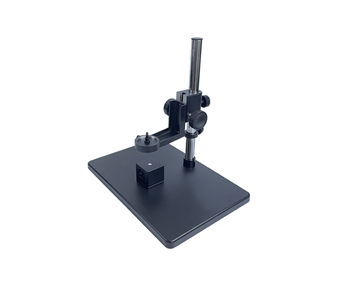

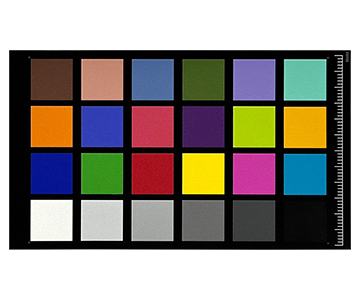

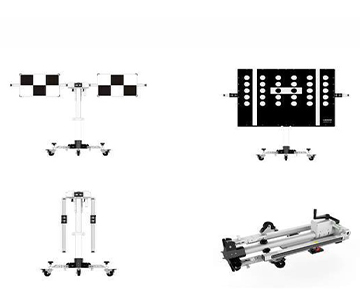

The mechanical structure of the FILMTHICK-C10 integrates an imported halogen tungsten lamp light source with a lifespan exceeding 10,000 hours, providing ample light source assurance for long-term stable measurements. Furthermore, this instrument can measure various parameters such as reflectivity, color, and film thickness, meeting the diverse needs for thin film characterization analysis in different fields.

Industry Applications: A Versatile Measurement Tool

-

Semiconductor Films: Precise thickness control is crucial for chip performance and reliability. The FILMTHICK-C10 can accurately measure semiconductor films, helping engineers understand film thickness, optimize production processes, and improve chip yield and performance.

-

Liquid Crystal Displays (LCD): The thickness uniformity of films directly affects display quality. The FILMTHICK-C10 can rapidly and accurately measure the thickness of LCD films, ensuring quality control during production and guaranteeing excellent display performance for every screen.

-

Optical Coatings: The optical coating industry demands high precision in film thickness, as even slight variations can significantly impact optical properties. With its high-precision measurement capability, the FILMTHICK-C10 meets the stringent requirements of this industry, assisting companies in producing high-quality optical components.

-

Biomedical Field: Thin film technology finds extensive application in areas like biosensors and drug delivery systems. The FILMTHICK-C10 enables non-destructive measurement of biomedical films, providing vital technical support for research and product development.

Technical Advantages: Multiple Algorithms and Integrated Software

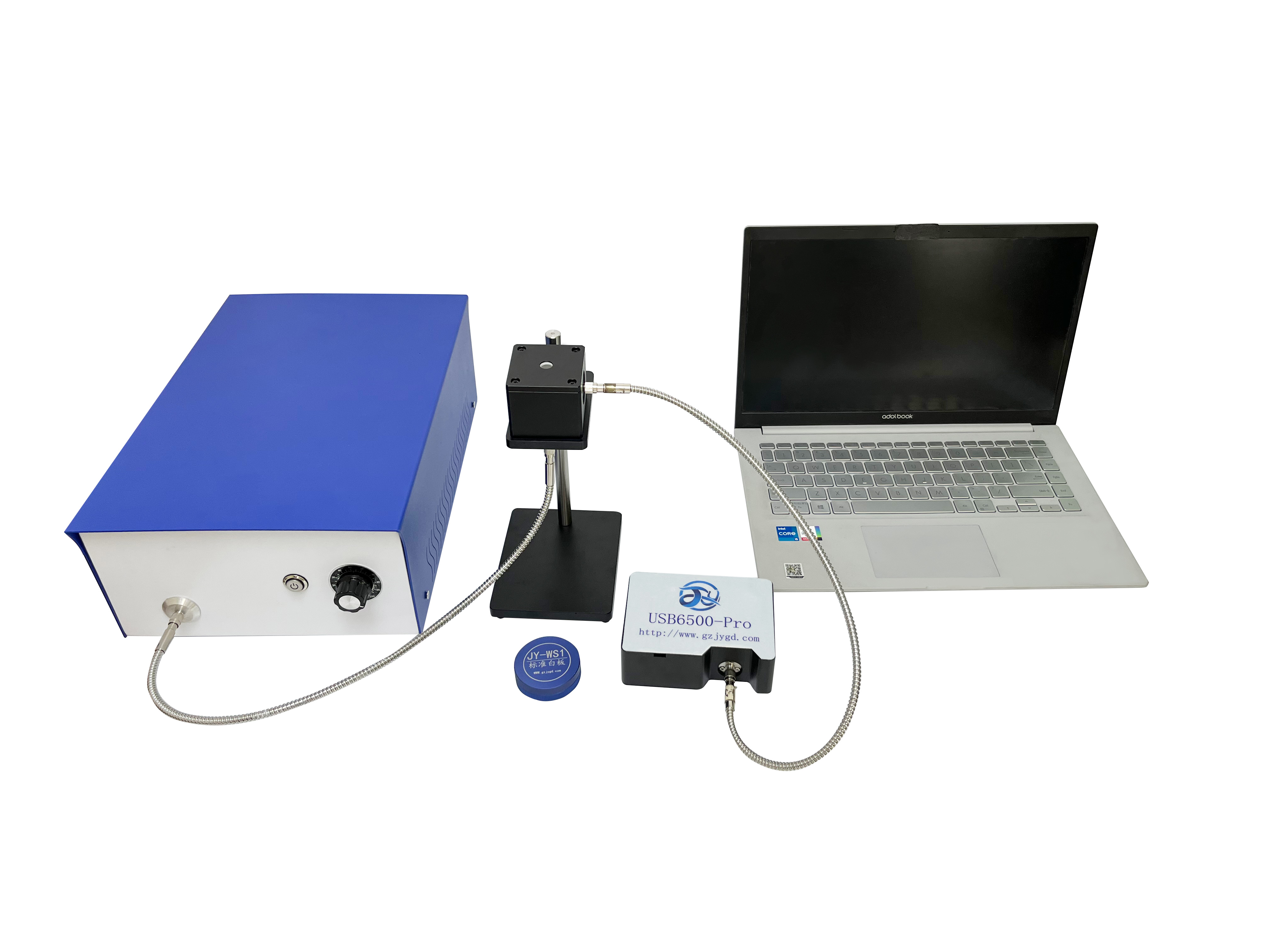

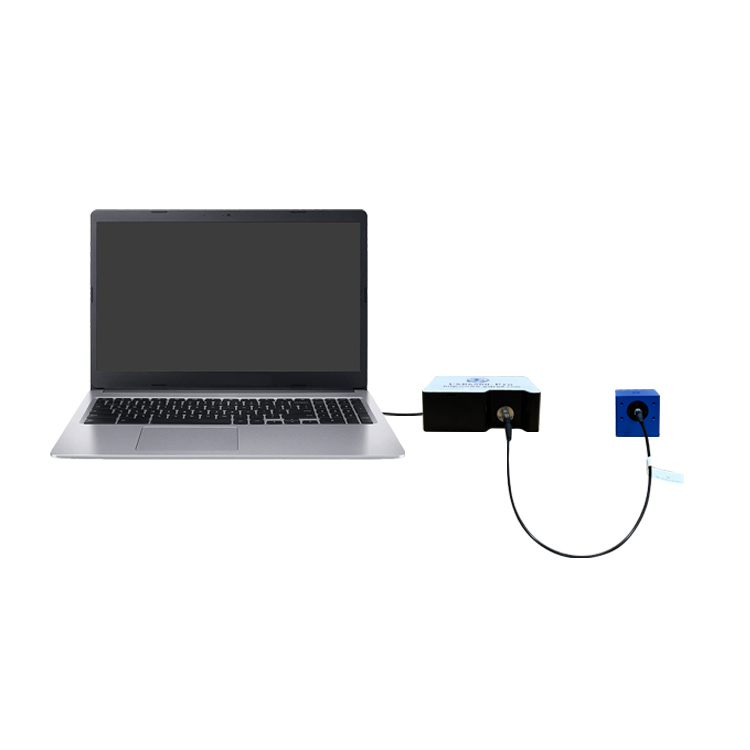

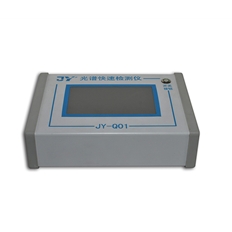

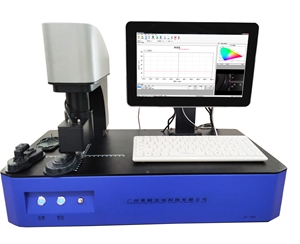

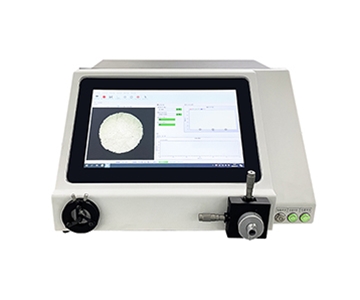

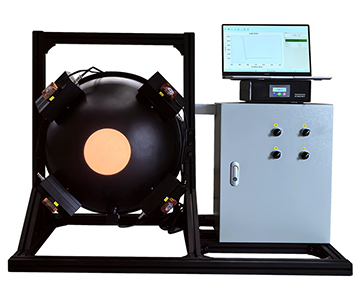

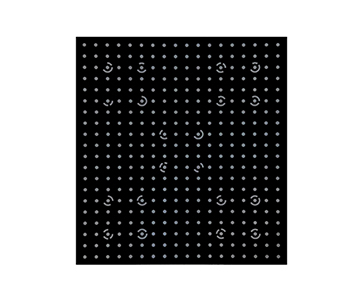

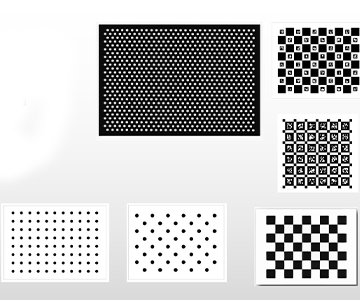

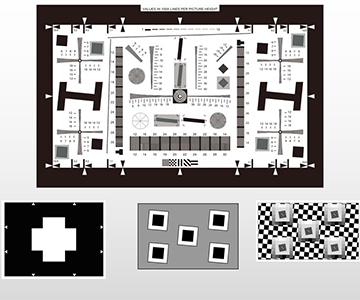

The Jingyi Optoelectronics OPTICAFILMTEST optical film thickness measurement software is a core strength of the FILMTHICK-C10. This software employs multiple algorithms, including FFT Fourier Transform, extrema method, and fitting method. It can automatically select the most suitable algorithm for data analysis based on different sample characteristics and measurement requirements, ensuring accurate and reliable results.

Additionally, the software includes a rich database of material refractive indices as well as an open material database. This eliminates the need for users to manually input parameters like refractive index, greatly enhancing measurement efficiency and convenience. The open database also allows users to add new material refractive index data according to their needs, further expanding the instrument's application scope.

During measurement, the software can display real-time trends of interference fringes, FFT spectra, and film thickness, allowing users to intuitively understand the measurement process and results. This real-time feedback mechanism helps users promptly identify and address issues, improving measurement accuracy and efficiency.

Key Points for Calibrating Film Thickness Detectors

-

Ensuring Environmental Stability: The stability of the measurement environment is crucial for the accuracy of a film thickness detector. Before calibration, ensure that environmental parameters like temperature and humidity are within the normal range. Environments with significant temperature fluctuations or air currents may cause measurement deviations and should be avoided for calibration.

-

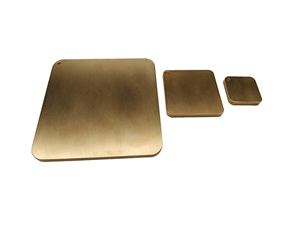

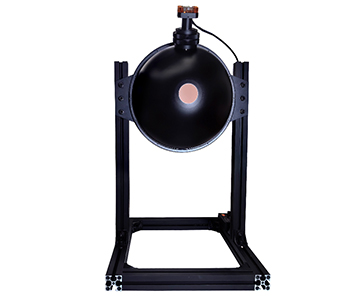

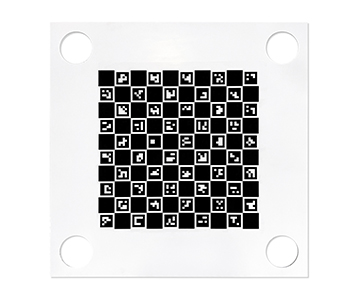

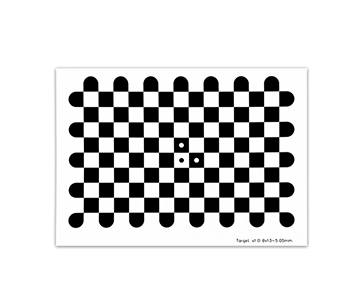

Calibration Using Reference Standards: Standard reference pieces are essential tools for calibrating film thickness detectors. The FILMTHICK-C10 typically comes with dedicated reference pieces for zero-point and sensitivity calibration. During calibration, the reference piece must be accurately placed on the instrument, and the zero-point and sensitivity calibration must be performed strictly according to the manual's procedures.

-

Regular Maintenance: Performing regular maintenance and inspection is vital for maintaining the instrument's stability and accuracy. Regularly clean the instrument's surface and sensor to remove dust and dirt that could affect measurements. Also, check all components for damage or looseness, and arrange for repair or replacement if any issues are found.

Usage Tips for Film Thickness Detectors

-

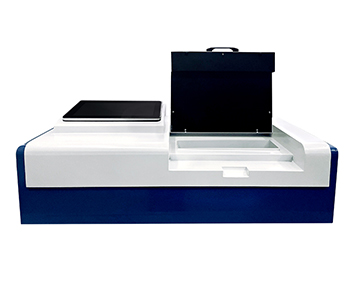

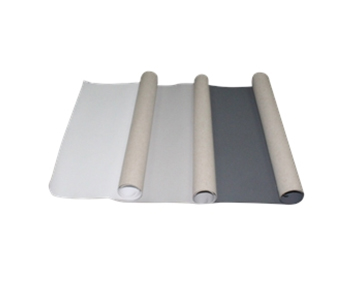

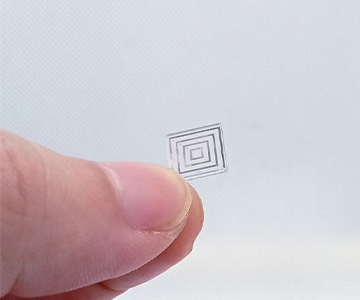

Sample Preparation: When placing the film sample on the measurement stage, ensure it is flat and clean. Scratches or stains on the sample surface may affect measurement accuracy. Therefore, carefully inspect and clean the sample surface before measurement.

-

Measurement Operation: After starting the instrument, select the appropriate measurement mode and parameters based on the sample characteristics and requirements. Ensure there are no obstructions between the instrument and the sample during measurement to avoid errors. Always follow the instrument's operating guidelines strictly to ensure a standardized and accurate process.

-

Result Analysis: After measurement, carefully analyze the results to check data accuracy and consistency. If anomalous data is found, re-measure or check for potential issues with the sample or instrument. When analyzing results, you can also refer to the trend graphs for interference, FFT spectra, and film thickness provided by the software to further assess result reliability and sample characteristics.

-

Data Storage and Backup: Save measurement data on a computer or other storage device and establish a data archive for subsequent analysis and comparison. Regularly back up data to prevent loss or corruption. Classifying and organizing the data can also facilitate better management and utilization.

Film thickness detectors are vital instruments in modern technology, and their proper calibration and usage are essential for ensuring accurate and reliable results. The Jingyi Optoelectronics FILMTHICK-C10, with its advanced technological principles and performance, provides effective measurement solutions across industries. By mastering the key calibration points and usage techniques, users can better leverage the instrument's capabilities, enhancing work efficiency and quality. We hope this article helps readers gain a deeper understanding of film thickness detectors and provides useful reference for their practical application.

#ThicknessGauge #FilmThicknessGauge #FilmThicknessDetector #FilmThicknessMeter #FilmThicknessMeasurementInstrument #FilmThicknessTester