Optical Power Integrating Sphere: A Key Instrument in Optical Detection

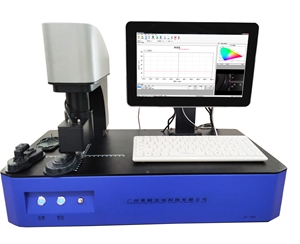

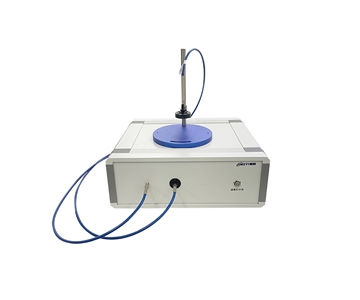

In the field of modern optical detection, the optical power integrating sphere serves as a critical optical device. It efficiently collects electromagnetic radiation emitted from external light sources and is widely used in applications such as flux measurement and optial attenuation.

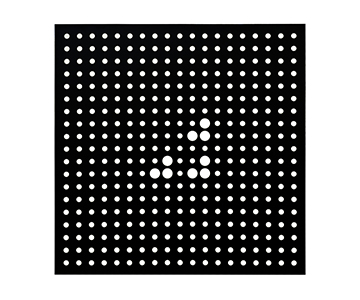

The core principle lies in the fact that when incident radiation strikes the reflective inner wall of the integrating sphere, it undergoes multiple diffuse reflections. This process results in highly uniform radiation distribution across the entire inner surface of the sphere. The cumulative radiation level on the sphere wall is proportional to the initial incident radiation, enabling precise measurement via a detector.

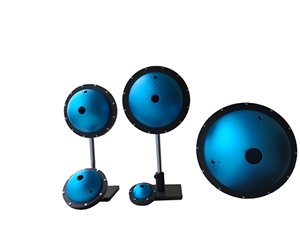

Among the key parameters of an optical power integrating sphere, its diameter plays a crucial role. Smaller-diameter spheres are generally more affordable but offer fewer and smaller usable ports, while delivering very high flux levels. In some cases, this high flux may even require the use of filters or fiber optic cables to prevent detector saturation. However, due to their relatively larger port-to-surface-area ratio, smaller spheres typically yield lower measurement accuracy compared to larger ones under identical conditions.

Conversely, larger integrating spheres produce lower flux and greater optical attenuation but offer higher signal-to-noise ratios and greater functional flexibility—at the cost of higher manufacturing expenses.

Sphere Material Significantly Impacts Performance

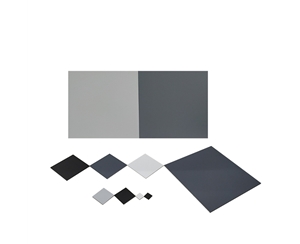

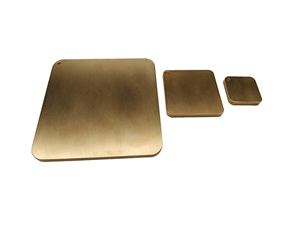

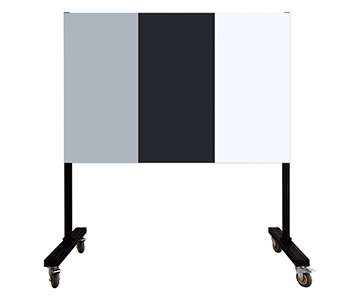

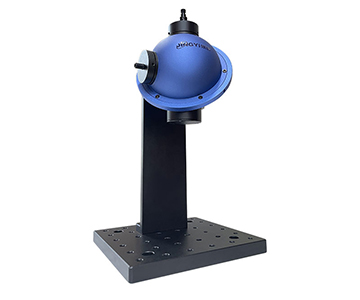

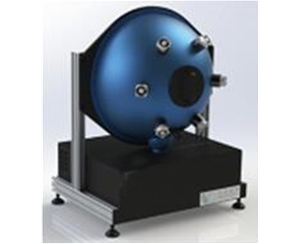

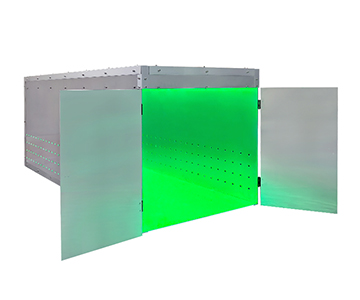

Common general-purpose integrating spheres are typically constructed from two aluminum hemispheres coated with a cost-effective reflective layer. The hemispheres are joined using anodized flange covers secured by screws. The standard coating provides effective reflectivity across the spectral range of 350–2400 nm, though reflectance slightly decreases beyond 1850 nm. This type is suitable for most radiometric applications in the visible and near-infrared spectrum.

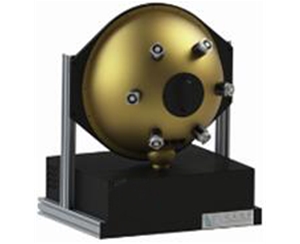

Diffuse gold coating—a metallic layer applied via electrochemical deposition—exhibits high reflectance in the near- and mid-infrared range (0.7–20 µm). Apart from the external surfaces and port frames also being gold-plated, its construction mirrors that of standard coated spheres. Gold-coated integrating spheres are particularly well-suited for infrared laser applications, as conventional coatings may lose reflectivity at elevated temperatures, whereas diffuse gold remains stable well above 100°C.

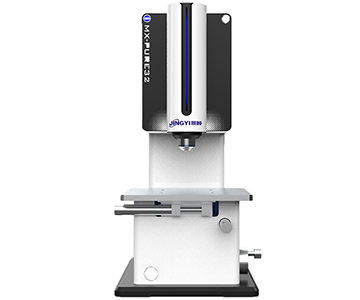

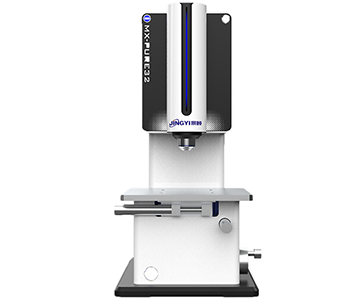

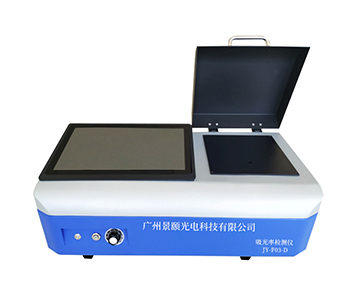

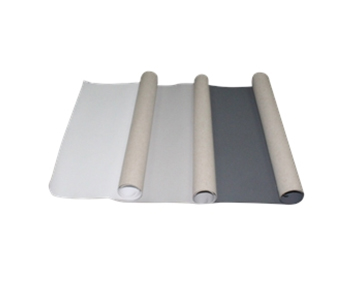

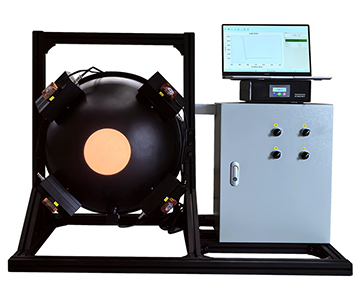

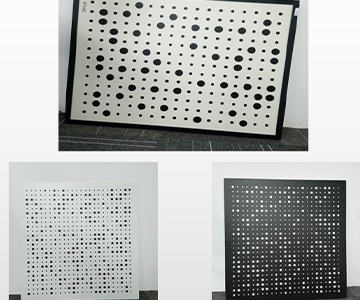

Polytetrafluoroethylene (PTFE) demonstrates high diffuse reflectance across 250–2500 nm, with especially high performance between 400–1500 nm. Jingyi Optics’ transmittance integrating spheres utilize imported high-diffuse PTFE material formed through high-temperature sintering. This material offers excellent Lambertian characteristics across the ultraviolet–visible–near-infrared spectrum (200–2500 nm), along with high stability, resistance to oxidation or yellowing, water resistance, and ease of storage—making it highly advantageous in practical applications.

PTFE integrating spheres can be visually identified by their 7 mm thick reflective walls visible through the ports. They consist of two hemispheres assembled into a spherical cavity and held together by an aluminum housing. Due to the mechanical machining and assembly required, PTFE spheres are more expensive than coated versions, and their available sizes vary based on wall thickness.

Because PTFE exhibits high reflectance and scattering properties—resulting in high internal flux—greater care must be taken when selecting port accessories and mounting fixtures.

Port Size and Placement Are Critical Design Considerations

Ports enhance the functional versatility of integrating spheres but simultaneously reduce the uniformity of internal light distribution. The ratio of total port area to the sphere’s internal surface area—known as the "port fraction"—is a key indicator of measurement accuracy. Spheres with lower port fractions generally deliver superior performance.

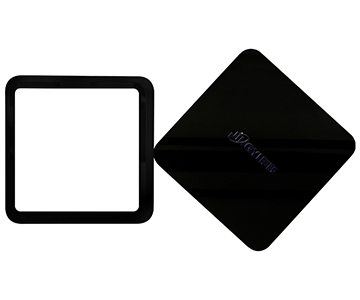

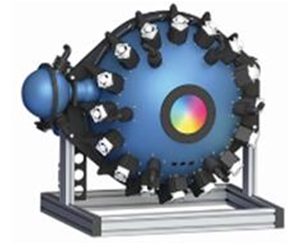

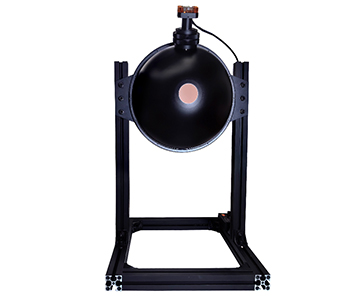

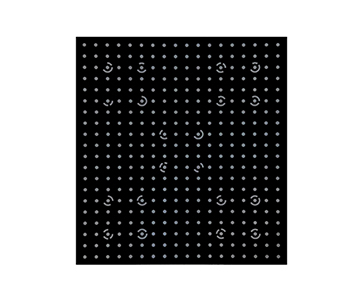

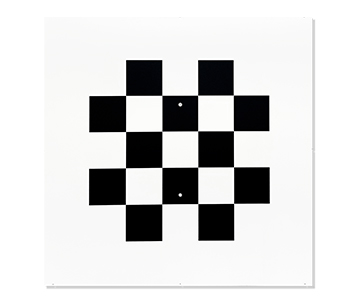

Each port on an integrating sphere serves a specific function, and improper usage can lead to inaccurate measurements. Ports are typically labeled at 0°, 90°, 180°, and the North Pole position. All ports are machined into the hemispherical shell at 90° intervals, with sizes determined by the sphere’s diameter and series.

During design, each port’s function is predefined: some serve a single purpose, while others support multiple functions. For instance, all general-purpose spheres can be used for both uniform light source generation and optical power measurement, while four-port spheres additionally support diffuse reflectance/transmittance measurements.

To ensure measurement accuracy, all integrating spheres include a baffle installed between the 0° and 90° ports. This baffle blocks direct-path radiation from the 0° input port from reaching the detector at the 90° port—a major source of error in total flux or radiant flux measurements.

Baffle materials vary by sphere type: aluminum baffles coated with appropriate reflective material are used in standard and gold-coated spheres and are fixed to the outer housing; in PTFE spheres, the baffle is machined from the same PTFE material.

Furthermore, correct port usage depends entirely on the specific application. A port suitable for certain optical components in one setup may be inappropriate in another. Some configurations may outperform others, even if both yield acceptable results.

Port Accessories Expand Functional Capabilities

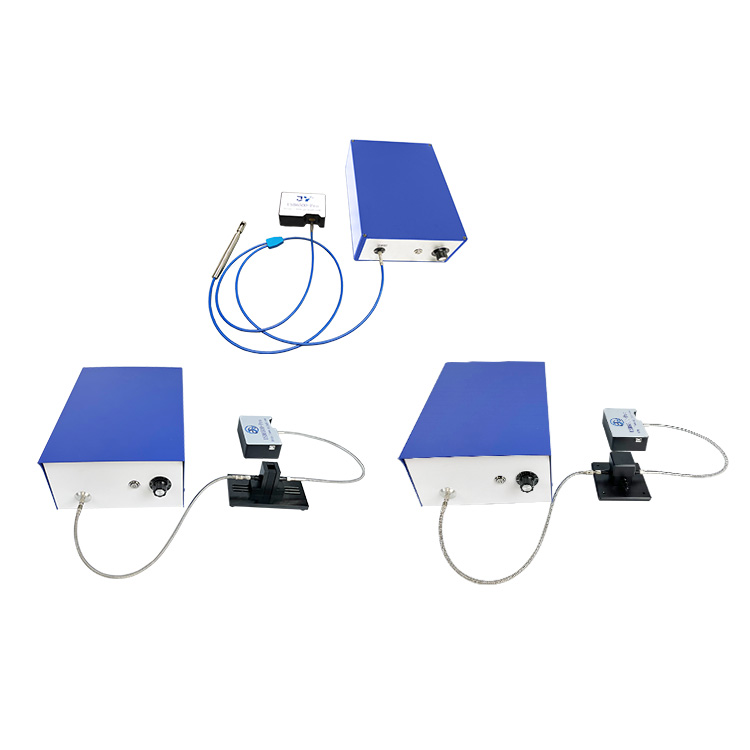

Each port features an aluminum frame to accommodate various accessories, including port plugs, aperture reducers, adapter rings, and fiber optic couplers. These enable a single general-purpose sphere to be configured for diverse applications—from uniform illumination to optical power measurement—and four-port spheres further support diffuse/transmission measurements.

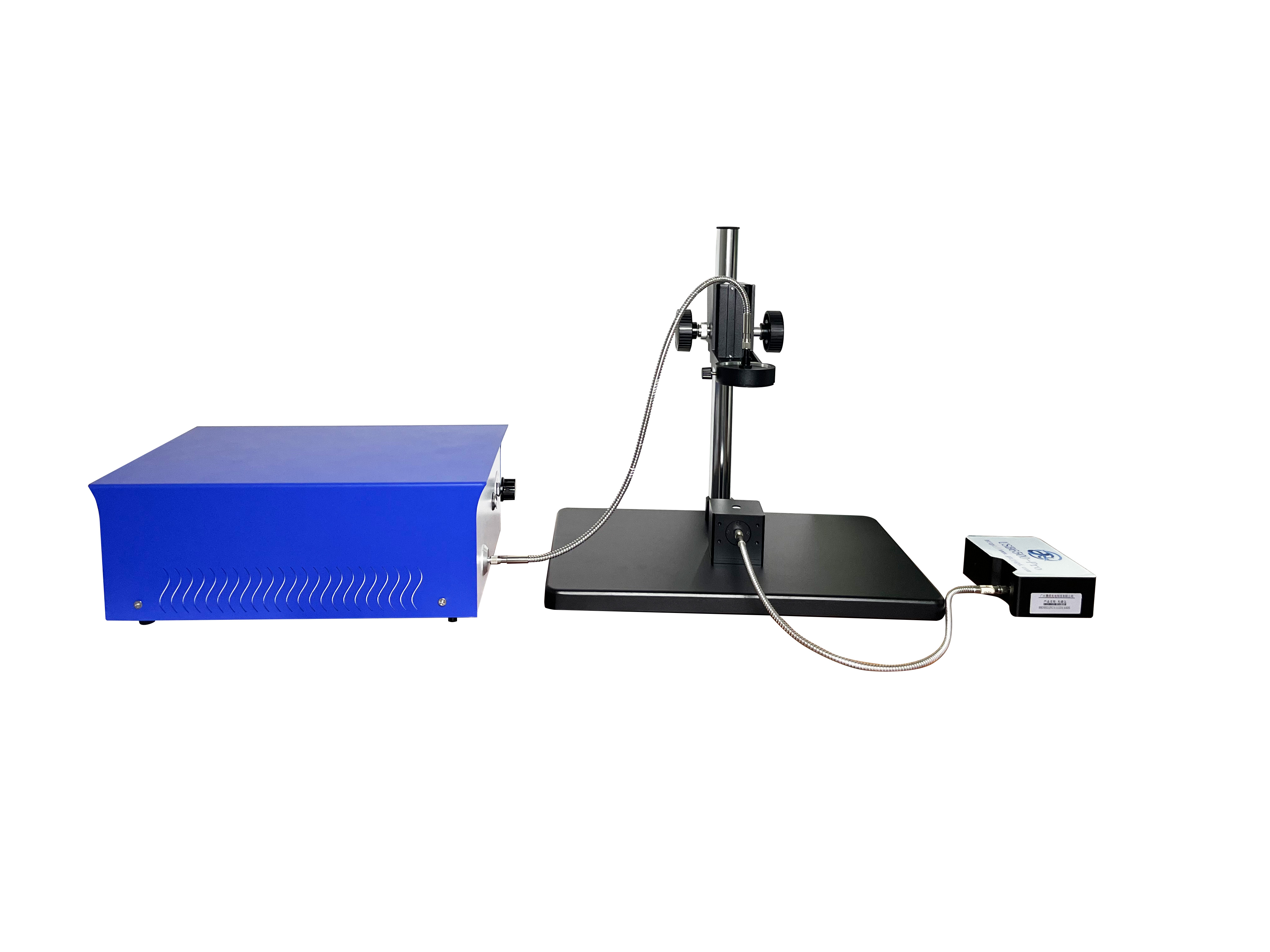

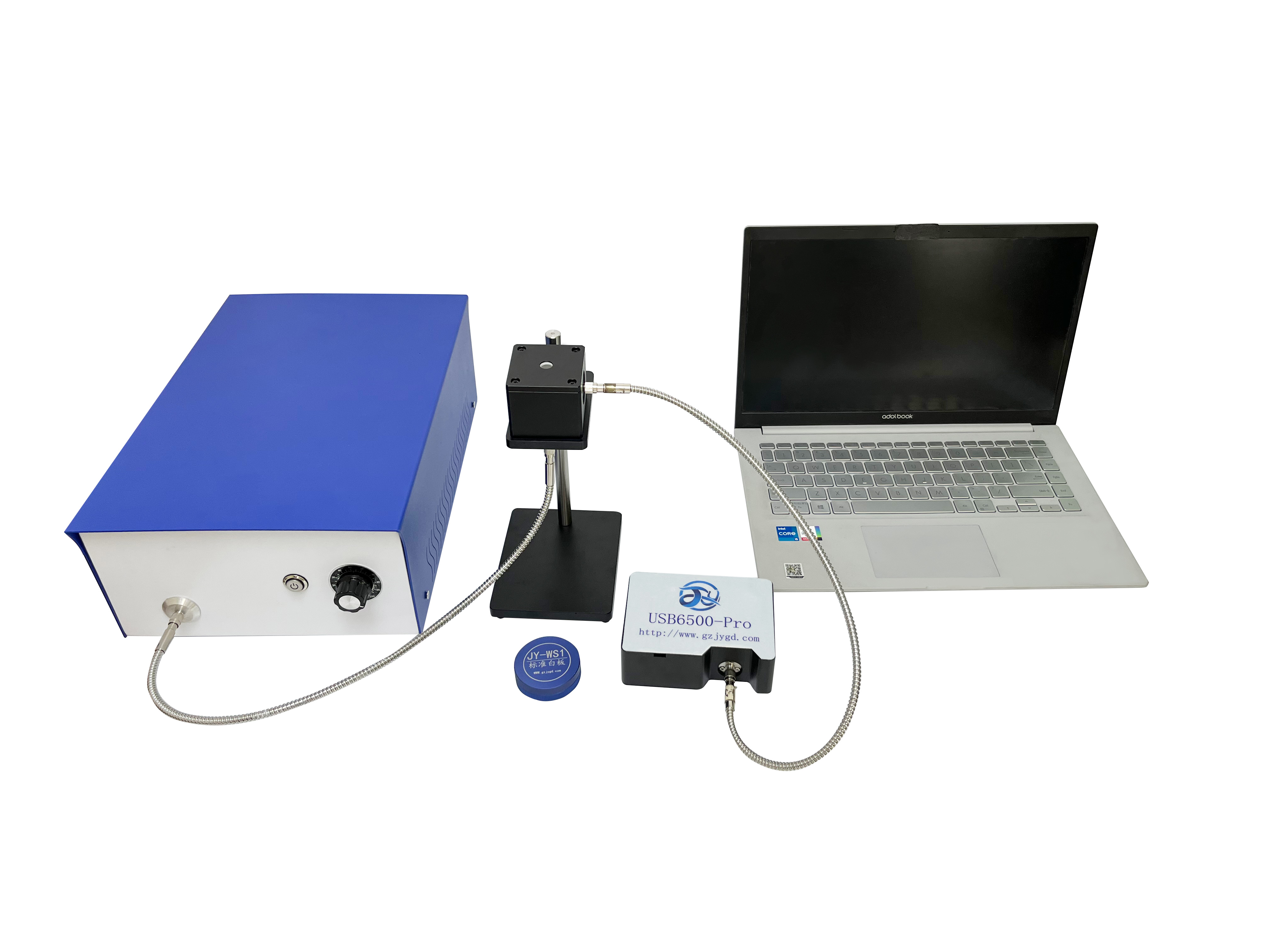

Practical Applications

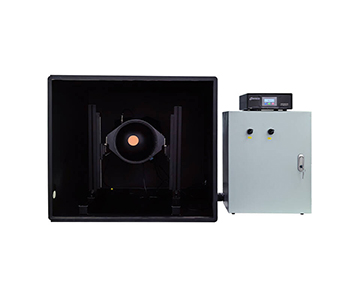

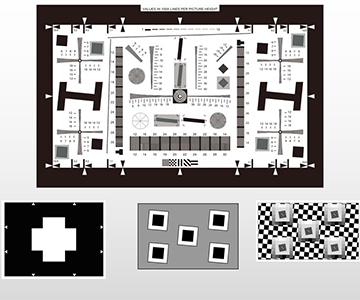

Collimated Laser Beam Power Measurement:

Measuring the total power of a collimated laser beam (regardless of polarization or beam collimation) is straightforward. The beam enters through the 180° port, creating a hotspot at the 0° port. With the detector at the 90° port, the baffle prevents direct radiation from the hotspot from hitting the detector, enabling spatially integrated power measurement. The North Pole port can serve as a pickup for wavelength analysis.

Divergent Source Power Measurement:

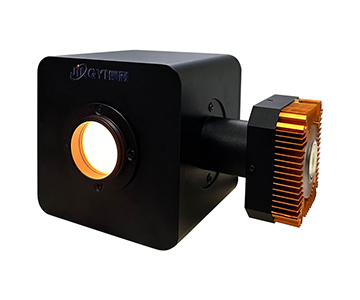

When paired with a calibrated detector, integrating spheres accurately measure the optical power of divergent sources such as laser diodes, lensed LEDs, and focused lamps. The source is placed at the 0° port, the detector at 90°, and the baffle blocks direct line-of-sight to the emission aperture. The North Pole port again serves for spectral sampling. Due to multiple internal reflections causing attenuation, integrating spheres are ideal for measuring high-power lasers.

Fiber Output Power Measurement:

Integrating spheres are also ideal for measuring fiber output power. Standard fibers emit slowly diverging beams, so the first reflection point isn’t highly concentrated—either collimated or divergent configurations work. For lensed fibers (higher NA), a divergent configuration is recommended; for collimated fiber outputs, a collimated setup is preferred.

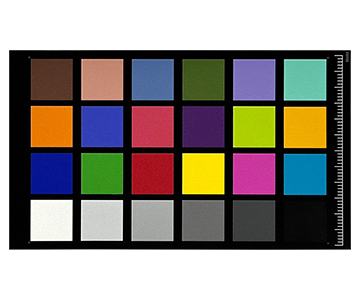

Transmittance Measurement:

Using a four-port sphere, transmittance is measured by collecting transmitted radiation from a sample placed at the 0° port. The result is compared against a direct-source measurement taken outside the sphere. The baffle shields the detector from non-integrated transmission. A light trap installed at the 180° port can eliminate unscattered light, enabling measurements of total integrated scatter, fluorescence, bulk scatter, and forward/backward scattering—with the detector at 90°.

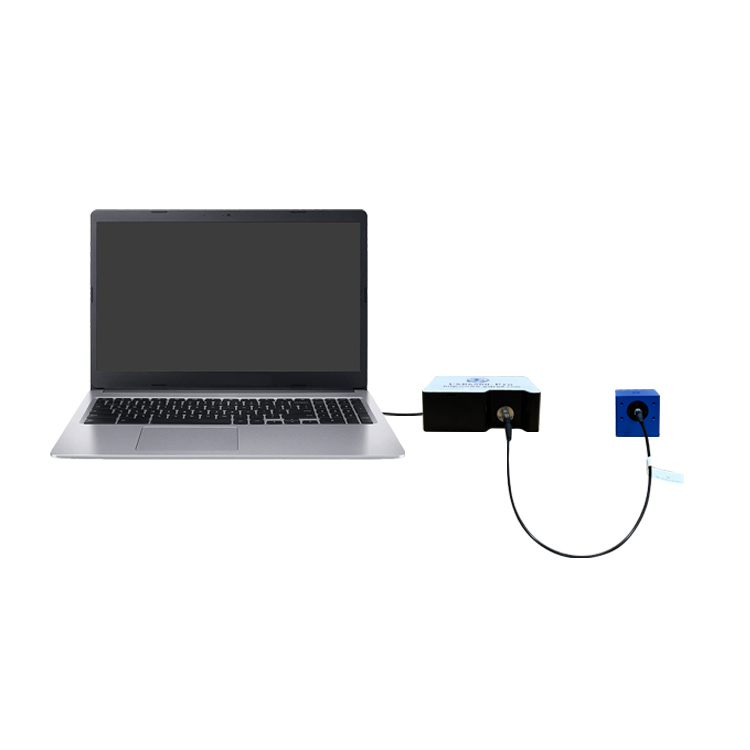

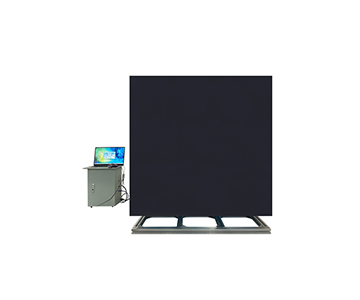

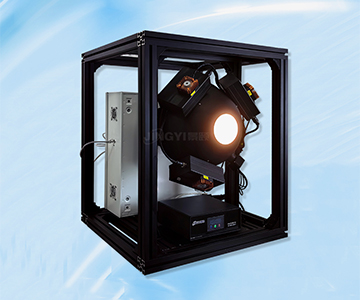

Uniform Light Source Configuration:

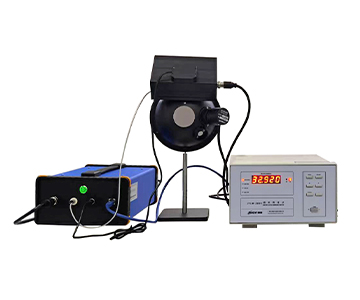

A general-purpose sphere can be configured as a uniform diffuse source by introducing external illumination. This setup requires a light source, a detector, and a power meter or radiometer. Three-port spheres are generally preferred over four-port versions for this application, as an unused fourth port (even with a plug) may disrupt output uniformity. Here, the light source connects to the 90° port, the detector mounts at the North Pole, and the 0° port serves as the uniform output. As long as the detector remains unsaturated, the output scales linearly with the power reading.

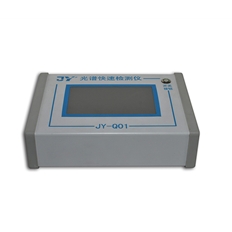

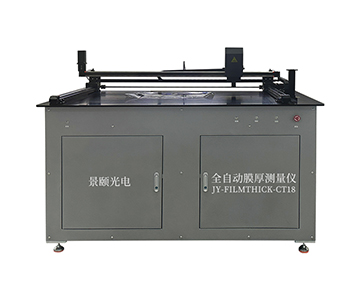

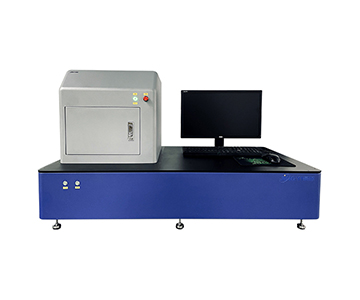

Jingyi Optics offers PTFE-based integrating spheres with high average reflectance, customizable sizes and interfaces, and comprehensive pre- and post-sales technical support. Typical applications include LED luminous flux testing, laser power measurement, display color calibration, and environmental monitoring—enabling high-precision optical metrology.

In summary, the optical power integrating sphere is a powerful and versatile tool in optical detection. Companies like Jingyi Optics continue to advance integrating sphere technology, delivering increasingly precise and efficient solutions that drive progress across the industry.

#FluorescenceQuantumYieldIntegratingSphere #RadiantIntegratingSphere #IntegratingSphere #OpticalPowerIntegratingSphere #Spray-CoatedIntegratingSphere